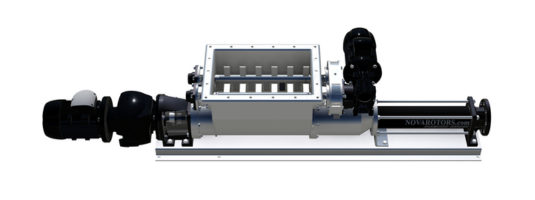

Progressing Cavity Pumps HE series

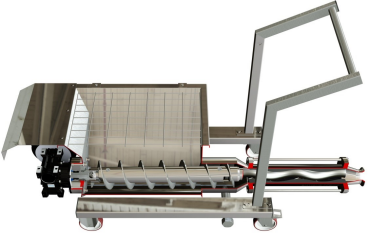

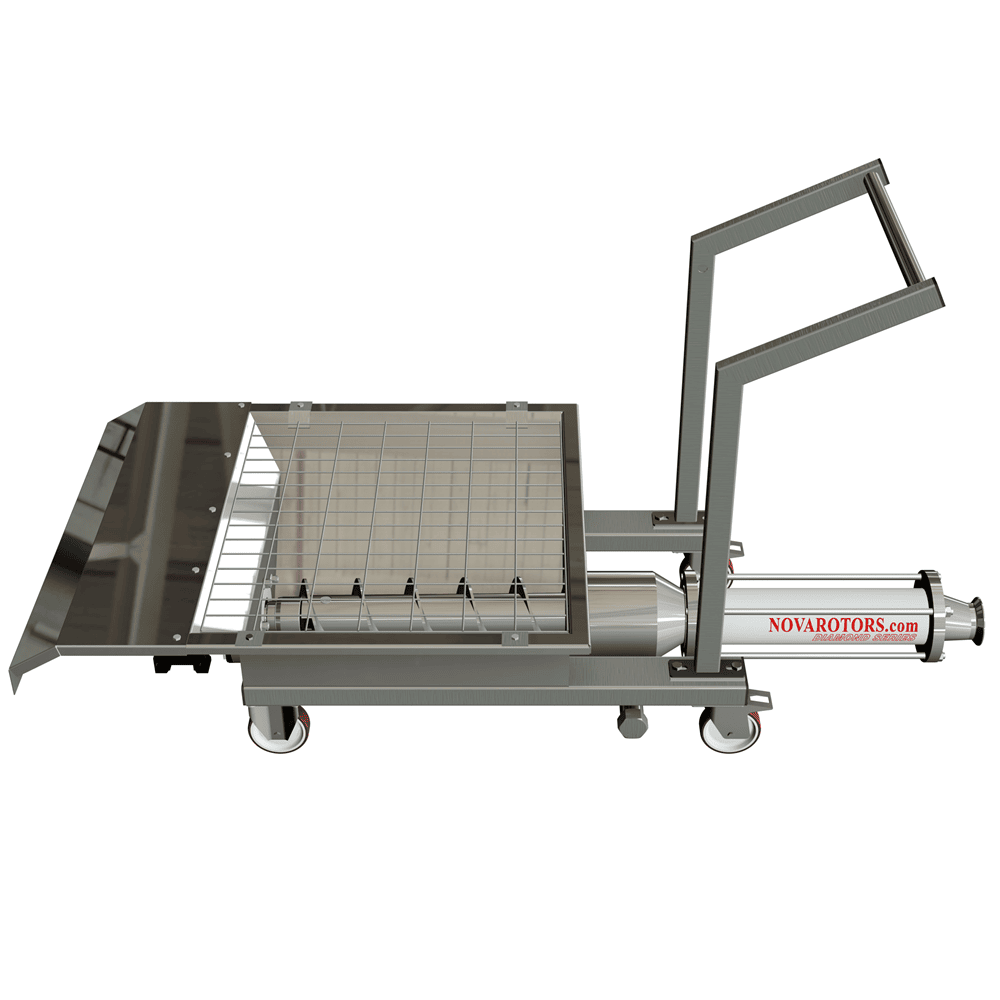

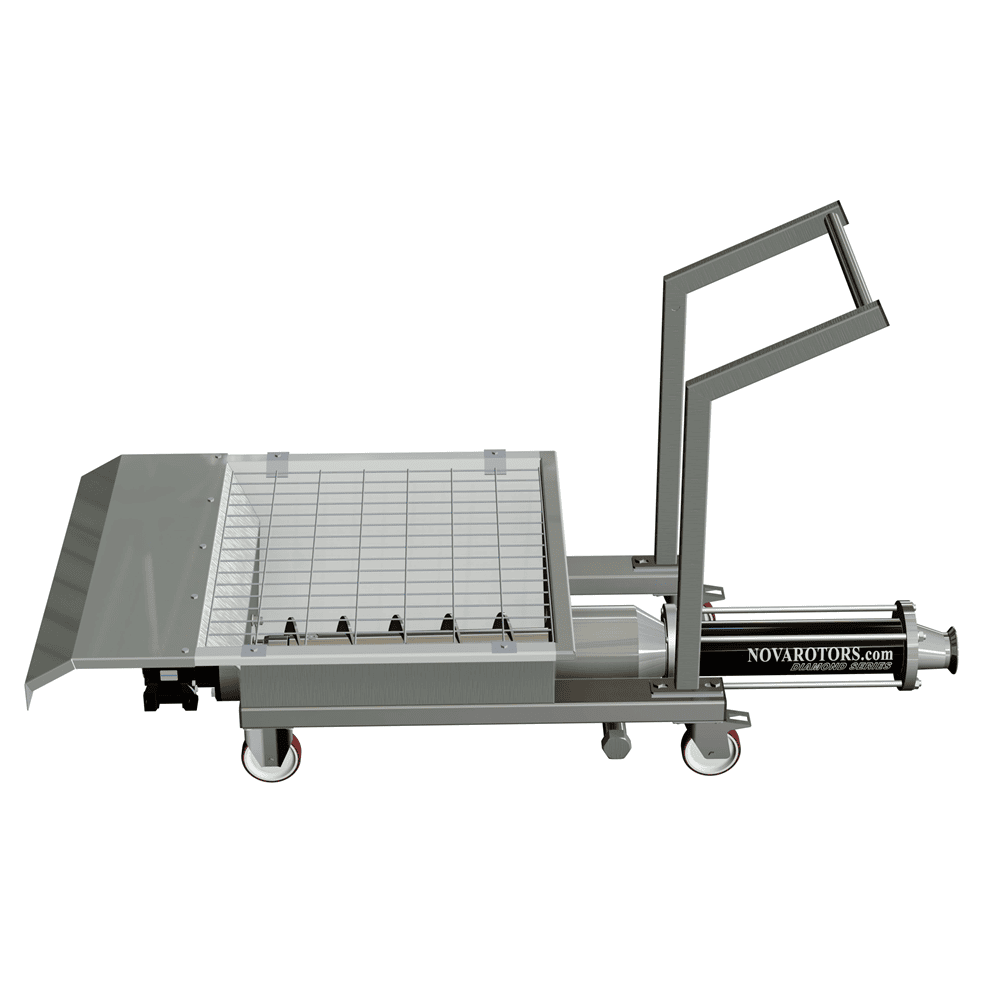

hopper pumps with trolley for food and winery sectors

Series with hopper an auger feed screw to convey directly the product to hydraulic part, are the ideal machines for pumping viscous and non-flowing, with a very high solids content.

Version with large eccentric rectangular hopper, auger feed screw, and integrated trolley. Ideal for enological sector in connection with the destemmer, for pumping the crushed grapes or without stalks. Extremely compact construction realized in stainless steel AISI 304 as standard, in all its components.

It is used a worm helical bevel gearbox to optimize the available space. As standard is supplied with welded mesh protection on the hopper, carter for motorization protection and e large handle suitable to implement electrical panel and inverter. Can be supplied with level probe into the hopper for automatic switching off of the pump.

Operating ranges

Flow rate

Pressure

Temperature

Applications

Discover the product's application characteristics Progressing Cavity Pumps HE series

Models

| Size | Model | QMAX 2 BAR [m³/h] | RPM MAX | P MAX [bar] |

|---|---|---|---|---|

| D020 | 1L1 | 4,9 | 1400 | 6 |

| D020 | 05K2 | 2,5 | 1400 | 12 |

| D020 | 025K4 | 0,7 | 800 | 24 |

| D025 | 2L1 | 10 | 1400 | 6 |

| D025 | 1K2 | 5,1 | 1400 | 12 |

| 05K4 | 05K4 | 1,5 | 800 | 24 |

| D025 | 025K8 | 0,7 | 800 | 48 |

| D030 | 4L1 | 14 | 1000 | 6 |

| D030 | 2K2 | 7,2 | 1000 | 12 |

| D030 | 1K4 | 2,9 | 800 | 24 |

| D030 | 05K8 | 1,5 | 800 | 48 |

| D040 | 10L1 | 22 | 800 | 6 |

| D040 | 4K2 | 11,5 | 800 | 12 |

| D040 | 2K4 | 4,2 | 600 | 24 |

| D040 | 1K8 | 2,4 | 800 | 48 |

| D040 | 16L1 | 32,5 | 800 | 6 |

| D040 | 8K2 | 16,8 | 800 | 12 |

| D040 | 4K2EL | 11,5 | 800 | 18 |

| D060 | 20L1 | 39,1 | 700 | 6 |

| D060 | 10K2 | 17,2 | 600 | 12 |

| D060 | 4K4 | 7,2 | 500 | 24 |

| D060 | 2K8 | 4,2 | 600 | 48 |

| D060 | 30L1 | 46 | 700 | 6 |

| D060 | 16K2 | 21,5 | 600 | 12 |

| D060 | 10K2EL | 17,2 | 600 | 18 |

| D120 | 40L1 | 65,5 | 600 | 6 |

| D120 | 20K2 | 31 | 600 | 12 |

| D120 | 10K4 | 11,7 | 400 | 24 |

| D120 | 4K8 | 7,3 | 500 | 48 |

| D120 | 60L1 | 82 | 500 | 6 |

| D120 | 30K2 | 40,5 | 500 | 12 |

| D120 | 20K2EL | 31 | 600 | 18 |

| D300 | 80L1 | 88 | 400 | 6 |

| D300 | 40K2 | 45 | 400 | 12 |

| D300 | 20K4 | 21 | 400 | 24 |

| D300 | 10K8 | 11,7 | 400 | 48 |

| D300 | 120L1 | 120 | 400 | 6 |

| D300 | 60K2 | 64,5 | 400 | 12 |

| D300 | 40K2EL | 45 | 400 | 18 |

| D400 | 160L1 | 161 | 400 | 6 |

| D400 | 80K2 | 90 | 400 | 12 |

| D400 | 40K4 | 45 | 400 | 24 |

| D400 | 20K8 | 19,5 | 350 | 48 |

| D400 | 240L1 | 261 | 400 | 6 |

| D400 | 120K2 | 116 | 350 | 12 |

| D400 | 80K2EL | 90 | 400 | 18 |

| D400 | 40K2E | 45 | 400 | 24 |

| D400 | 20K4E | 19,5 | 350 | 48 |

| D500 | 320L1 | 255 | 350 | 6 |

| D500 | 160K2 | 142 | 350 | 12 |

| D500 | 80K4 | 56 | 250 | 24 |

| D500 | 40K8 | 26 | 250 | 48 |

| D500 | 480L1 | 368 | 350 | 6 |

| D500 | 240K2 | 185 | 350 | 12 |

| D500 | 160K2EL | 142 | 350 | 18 |

| D500 | 80K2E | 56 | 250 | 24 |

| D500 | 40K4E | 26 | 250 | 48 |

| D600 | 640L1 | 540 | 350 | 6 |

| D600 | 320K2 | 280 | 350 | 12 |

| D600 | 160K4 | 101 | 250 | 24 |

| D600 | 80K8 | 51 | 250 | 48 |

| D600 | 960L1 | 802 | 350 | 6 |

| D600 | 480K2 | 403 | 350 | 12 |

| D6 | 320K2EL | 280 | 350 | 18 |

| D600 | 160K2E | 142 | 250 | 24 |

| D600 | 80K4E | 56 | 250 | 48 |

Materials

Casing materials

Stainless steel hopper and outlet port,

Coatings

On request, solutions such as fluoropolymers and ceramic coatings to ensure superior performance.

Seal Shaft Materials

Stainless Steel materials with at request advanced coatings to ensure long-lasting durability and resistance.

Materials of Rotors

Stainless Steel materials with at request advanced coatings to ensure long-lasting durability and resistance.

Materials of Stators

We offer a wide selection of compound materials for stators, designed to ensure high performance and durability in diverse industrial environments.

Among the available options, we can provide elastomers and special materials, including food-grade compounds and high-performance solutions.

These solutions can be customized based on the specific needs of the customer and the operating conditions.

Connections

Flanges and threaded connections for various applications, including Macon and Garolla

Sealing Systems

Lip seal, mechanical seals, Gland packing seal B01

(For construction details, see the brochure sealing systems and seals)

Bases

Trolley (cart) with handle integrated on the hopper construction

(For details, see the brochure constructive options, equipment and

Optional

Control devices

Control panel

Control panel with inverter

Drive with integrated inverter

(For details, see the brochure constructive options, equipment and installations)

Equipment and optional

Eccentric Outlet

(For details, see the brochure constructive options, equipment and installations)

Variants

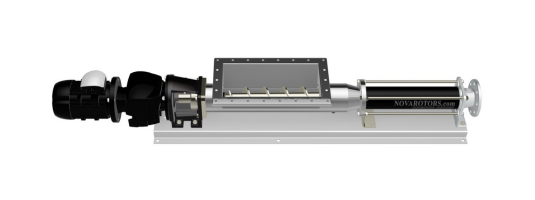

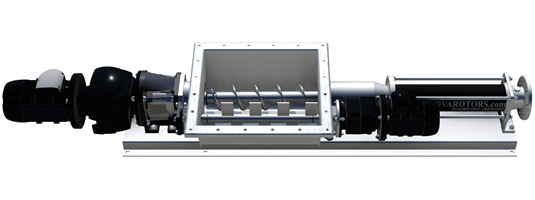

DHE Series

The motorization is integrated into the machine construction. Angle gearboxes of the worm type are used, this allows to have a remarkable axial compactness, following the dimensions of the eccentric hopper. The reducer is coupled by a male shaft at the pump inlet. The protective housing installed on the hopper protects the motor preventing its deterioration.

DHE Series

The motorization is integrated into the machine construction. Angle reducers of the worm type are used, this allows to have a remarkable axial compactness, following the dimensions of the eccentric hopper. The reducer is coupled by a male shaft at the pump inlet. The protective housing installed on the hopper protects the motor preventing its deterioration.