Progressing Cavity Pumps M series

Dosing series for industrial and environmental sector

The Diamond M series represents the best solution for the industrial sector in dosing a wide range of fluids. They are synonymous with robustness, reliability, performance, and application flexibility.

Designed according to the most demanding standards, they are suitable for dosing both viscous and non-viscous products, with or without solids of any kind. They offer an ideal solution for those seeking a high-tech standard product with an unmatched cost-benefit ratio in the current progressive cavity pump market.

The DM, JM, and FM series stand out for their pump-to-motor coupling type.

Operating ranges

Flow rate

Pressure

Temperature

Applications

Discover the product's application characteristics Progressing Cavity Pumps M series

Models

| Size | Model | QMAX 2 BAR [m³/h] | RPM MAX | P MAX [bar] |

|---|---|---|---|---|

| D020 | 05L1 | 2,7 | 1400 | 6 |

| D020 | 025K2 | 1,4 | 1400 | 12 |

| D020 | 012K4 | 0,5 | 1000 | 24 |

| D020 | 012K2 | 0,6 | 1400 | 12 |

| D020 | 006K4 | 0,2 | 1000 | 24 |

| D020 | 003K4 | 0,1 | 1000 | 24 |

| D020 | 0015K4 | 0,05 | 1000 | 24 |

Materials

Casing materials

Wide selection of: cast iron, alloys and stainless steels, Polypropylene including corrosion-resistant options for harsh environments.

Coatings

Solutions such as fluoropolymers and ceramic coatings to ensure superior performance.

Seal Shaft Materials

Steel and special alloy materials with advanced coatings to ensure long durability and resistance, as well as advanced protective coatings such as ceramic oxides and tungsten carbide.

Optional for coupling rod

Open Joint

titanium flexible shaft

(For details, see the brochure constructive options, equipment and installations)

Materials of Rotors

Steel and special alloy materials with advanced coatings to ensure long-lasting durability and resistance.

Materials of Stators

We offer a wide selection of compound materials for stators, designed to ensure high performance and durability in diverse industrial environments.

Among the available options, we can provide elastomers and special materials, including food-grade compounds and high-performance solutions.

These solutions can be customized based on the specific needs of the customer and the operating conditions.

Connections

Flanges and threaded connections for various applications, including food-grade models and high-pressure environments.

Sealing Systems

Various types of mechanical seals, both single and double, cartridge-style; also available with flushing solutions in accordance with API standards.

Bases

- standard Base

- API 676 Base

- Base with anti-vibration housing (feet spacer)

- Base with risers

- Skid with lifting devices

- Cart for industrial sector (trolley)

- Cart for food grade and winery sector

(For details, see the brochure constructive options, equipment and installations)

Optional

Equipment and optional

- Stator heating jacket

- Temeprature probe for dry running protection (standard in the ATEX version)

- Flow switch

- Heating jacket for body pump

- Stainless steel stator cover

- Industrial flanged Bypass (or with threaded connection)

- Quench Pot flushing

- Stainless Steel Lantern

- Hermetic lantern

- Carter to protect the motorization

(For details, see the brochure constructive options, equipment and installations)

Variants

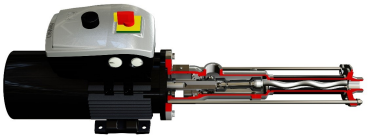

DM Series

The motor is directly coupled to the pump by means of a flange. This solution is extremely cost-effective and compact, significantly reducing installation costs and simplifying maintenance. The forces generated by the hydraulic part are supported by the motor. Each motor used has been suitably selected on the basis of restrictive technical parameters and subjected to numerous durability tests under heavy loads. The DM series is the reference point for almost all pumps installed in industry.

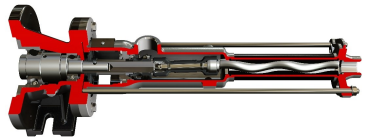

JM Series

The motor is connected to the pump input shaft via coupling. It is the best solution in terms of performance and durability. All the forces generated by the pump are absorbed by the bearings in the support. These bearings have a very high load resistance. They are mounted with extreme precision on components of the highest quality. It is the best solution when you want to ensure maximum durability and reliability, while requiring larger installation spaces. The bearing holder designed by us is modular and can be installed later in a pump with monoblock holder of the DM series. Represents the state of the art in this type of installation.

FM Series

The motor is directly coupled to the pump via the flange of the bearing support module. This solution is the most versatile as it allows the use of standard flanged gearboxes and output shaft, coupling with hydraulic or pneumatic motors, maintaining the simplicity and compactness of the classic monobloc solution while guaranteeing total reversibility and superior bearing support performance.

This bearing support module can be applied to the entire Diamond series and allows for quick maintenance of the motor drive. FM is therefore synonymous with modularity and reliability with any type of motor.

DETAILED CHARACTERISTICS