Production of Essential Oils from Onions

Introduction

Onions are among the oldest cultivated vegetables and offer numerous health benefits. However, cutting and peeling them often cause eye irritation, making these processes unpleasant. As a result, the demand for ready-to-use onions, such as peeled, pre-cut, or dehydrated onions, is continuously growing.

The industrial processing of onions to meet this demand generates a significant amount of organic waste, primarily consisting of outer skins and discarded portions of the bulbs. Proper disposal of these residues poses a challenge for companies in the sector, as they contain sulfur compounds that give off a particularly strong odor.

Oil? A New Life for Organic Waste

Despite being considered waste, these materials can be repurposed for alternative uses. Onion waste can become a valuable resource for developing functional foods and nutraceuticals, as well as for energy and biogas production. Various studies have shown that, within the framework of a circular bioeconomy, it is possible to extract useful biomolecules from these residues.

Onion skins, in particular, contain natural compounds that can help combat oxidative stress, microbial infections, and even certain types of cancer. Onion extracts are believed to have antimicrobial, antibacterial, antidiabetic, anti-obesity, antithrombotic, and anticancer properties, as well as contribute to lowering total cholesterol levels.

Client Company and Their Needs

The client company harvests onions for sale and utilizes lower-quality ones to produce essences and polyphenolic compounds. Additionally, following a green approach, they reuse processing waste to generate energy until the spent product is transferred to a biogas plant. In the future, they aim to establish their own energy production facility.

Client’s Request

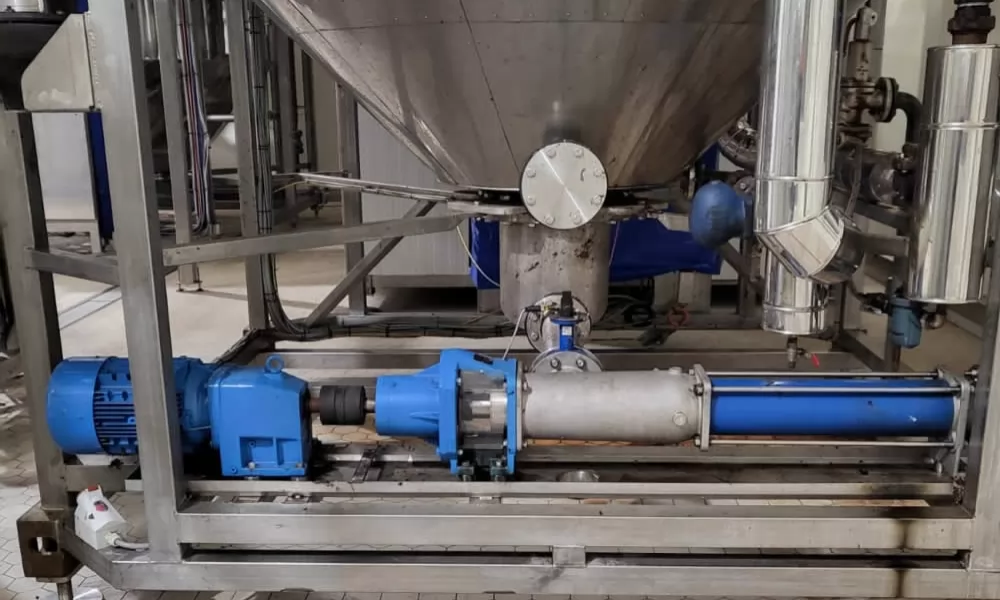

To transport the product from silos to the digester, cooked onions proceed to the extractor, which derives essences and oils, while waste is pumped to the recovery system. The client was searching for a suitable machine for this purpose, considering that onions are perishable and must be pumped into tanks at a distance.

The Challenge

Pumping onions over long distances with a progressive cavity pump presents several technical challenges:

- High abrasiveness and wear – Onion skins and fibers can cause premature wear of the stator and rotor, reducing pump lifespan.

- Varied consistency – Whole, peeled, or pre-cut onions have different consistencies, making it difficult to maintain a uniform flow.

- Presence of air – If the product contains a lot of air, the pump may lose priming, reducing pumping efficiency.

- Block formation – Onion pieces can aggregate and create clogs in the pipeline or pumping chamber, especially if not properly processed.

- Hygiene concerns – Decomposing onion residues can generate unpleasant odors and require frequent cleaning to avoid contamination.

- Transfer distance – If the distance is significant, sufficient pressure must be ensured to prevent flow losses or the need for intermediate pumps.

- Viscosity and solid content – If onions are processed into a puree, their viscosity can vary, affecting pump performance.

Process Steps

- Step 1: The FSH-R hopper pump moves onion pieces 300 meters to a collection tank.

- Step 2: The DH pump transfers the onions from the collection system to the cooking plant.

- Step 3: The JN flanged pump transfers the boiling onion soup to the oil extraction and separation plant.

The spent onions, a mixture of onions and water, are then loaded onto trucks and transported to a biogas plant.

Issues Before Pump Installation

Nova Rotors conducted a trial at its facilities to test the pump performance. The client provided several containers of pre-processed onions, which were brought to temperature and pumped over a distance to verify flow rate, pressure, and head loss.

The primary challenge identified during testing was the high temperature of the onions, which could not be fully replicated in the test system except for small quantities. Additionally, it was crucial to preserve the quality of the onions before extracting the essences.

The Solution

To ensure efficient transfer, the following pumps were selected:

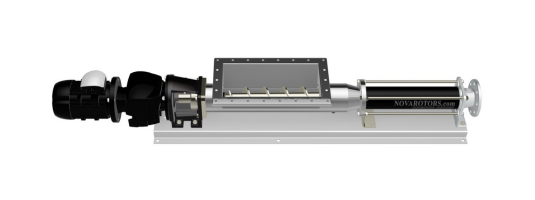

- FSH-R hopper progressive cavity pump with an auger for pumping high-temperature mixtures.

- DH progressive cavity pump for transferring the product to the cooking plant.

- JN flanged progressive cavity pump for sending boiling onion soup to the oil extraction and separation plant.

Results

- Improved operational efficiency: Onion and waste transfer is now continuous and reliable.

- Reduced maintenance costs: The selected pumps exhibited lower wear compared to previous solutions, reducing management costs.

- Optimized energy production: Waste is now transported more efficiently to digesters, maximizing biogas recovery.

- Preserved product quality: Gentle pumping prevented damage to the onions, maintaining their characteristics before extraction.

Conclusion

Thanks to its collaboration with Nova Rotors, the client has improved production process management, optimizing the supply chain and reducing environmental impact. The client plans to expand the system with additional pumps to increase waste treatment capacity and maximize biogas production, reinforcing its commitment to an efficient and innovative circular economy.

Products used