Production of Essential Oils from Onions

Introduction

Efficiency and Reliability in the Sugar Industry

In sugar production, whether from sugar cane or sugar beet, our progressive cavity pumps ensure precise and gentle transfer of high-viscosity fluids like molasses and syrup. Thanks to their ability to handle dense and viscous liquids without altering their properties, they are the ideal solution for juice extraction, evaporation, crystallization, and purification stages.

Main applications in the sugar sector:

Extraction and transfer of molasses after centrifugation

Syrup recirculation in evaporation systems

Accurate dosing into storage tanks and mixers

Transport of viscous fluids or ethanol and alcohol, even at high temperatures

Our pumps are especially suitable for:

Juice extraction from sugar cane and sugar beet

Molasses and syrup handling in crystallization processes

Dosing and transfer of viscous liquids during treatment and storage phases

Constructed in AISI 304 stainless steel, our pumps offer high durability and easy cleaning, ensuring compliance with the highest hygiene standards.

Key benefits of our progressive cavity pumps:

Low energy consumption and continuous operation thanks to a constant, pulsation-free flow

Suitable for handling hot and viscous fluids up to 80°C, with viscosities up to 15,000 mPas

Reliable and optimal performance even under demanding operating conditions

Our progressive cavity pumps are the ideal choice to ensure maximum control throughout all stages of sugar production, improving efficiency and optimizing the process.

Efficiency in Pumping High-Viscosity Sugary Fluids: The Role of Progressive Cavity Pumps in Sugar Processing

🏭 Context

A company involved in cane sugar production needed a reliable solution for transferring molasses and sugar syrup during various stages of the production process. Both fluids are highly viscous, sometimes containing solid residues or suspended crystals, and require a gentle, continuous, and robust pumping system.

Challenge

Transfer of molasses (high density, by-product of the centrifugation process)

Pumping of concentrated sugar syrup during and after evaporation

Need for a constant, pulsation-free flow

Resistance to abrasive, sticky, and corrosive fluids

Preserving product integrity (no damage to crystals)

One of the main critical issues was the significant distance between the suction point and the pump, causing cavitation and flow interruptions. The system also had to handle dense fluids at temperatures up to 40/60 °C in another sugar production facility.

✅ Adopted Solution

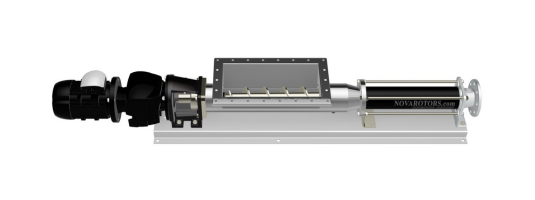

Progressive cavity pumps (e.g., model XYZ) were installed at various points of the production line:

Extraction and transfer of post-centrifugation molasses

Recirculation of syrup in the evaporation systems

Dosing into storage tanks and mixers

Selected pump features:

AISI 316 stainless steel body

Elastomer stator resistant to sugary fluids

Operation with fluids up to 100,000 mPas

Adjustable flow and self-priming capability

💡 Achieved Results

Steady and controlled flow without pulsations → improved production output

Higher reliability compared to alternative systems (e.g., diaphragm or centrifugal pumps)

Reduced maintenance due to wear and fouling resistance

Product quality preserved: no degradation or foaming

Optimal handling of even high-temperature fluids

📊 Technical Data (example)

| Fluid | Viscosity | Temperature | Flow Rate | Pressure |

|---|---|---|---|---|

| Molasses | 5,000–15,000 mPas | 40–60 °C | 5–54 m³/h | 4 bar |

| Sugar syrup | 2,000–10,000 mPas | 70–80 °C | 3–30 m³/h | 3 bar |

🧩 Conclusion

Progressive cavity pumps proved to be the ideal solution for handling molasses and sugar syrup, ensuring consistent performance, minimal maintenance, and excellent compatibility with challenging fluids. A reliable system for plants requiring continuous operation and high product quality.

Products used