Wastewater Treatment and Sludge Processing

Nova Rotors Technology for Optimizing Treatment Processes

Sludge treatment is essential for purifying wastewater from industrial processes and municipal discharges. The extensive use of water generates large volumes of effluents that require specific treatment to remove harmful substances before being released back into the environment. Wastewater treatment plants play a crucial role in this process, eliminating impurities through the use of activated sludge. However, this treatment generates semi-solid byproducts, known as thickened sludge, which must be either disposed of or repurposed.

Thanks to technological advancements, these materials can now be reused in sectors such as biogas production or as natural fertilizers, contributing to a sustainable circular economy.

In this context, progressive cavity pumps are the ideal solution for handling high-viscosity sludge with a high solids content. Their ability to ensure operational efficiency, continuous performance, and low maintenance costs makes them essential for optimizing sludge treatment plant operations.

Nova Rotors Pumps for Wastewater Treatment

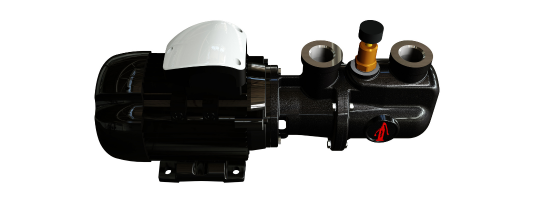

N SERIES

Flanged Industrial Pumps: Ideal for the most demanding applications, designed for the transfer of thickened and chemical-physical sludge.

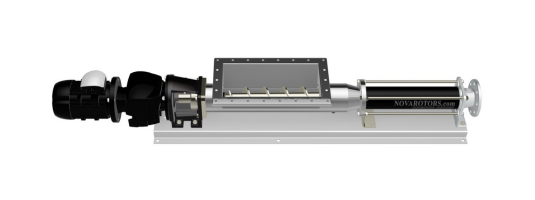

H SERIES

Hopper and auger version, perfect for pumping low-flowability materials that do not tend to form bridges.

HS SERIES

Rectangular hopper pump with a wide auger, ideal for high-viscosity fluids with up to 35% dry matter content.

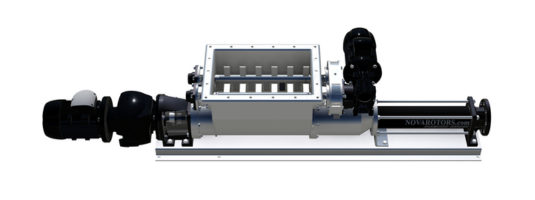

HB SERIES

Double-Shaft Bridge-Breaker Hopper Pump

Designed for highly viscous materials with up to 35% dry matter content that tend to form clogs or bridges.

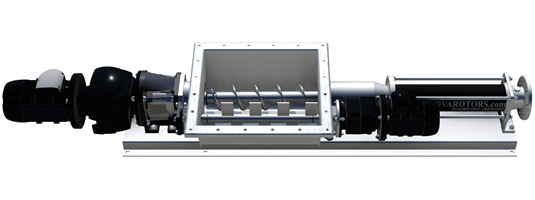

HSB SERIES (DHS with “B” MODULE)

Evolution of the DHS, equipped with the “B” Module, a device that feeds the auger to prevent bridge formation, ideal for materials with up to 40% dry matter content.

V SERIES

Submersible Vertical Pump: Designed for direct pumping from tanks or wells, fully customizable in length. Available in stainless steel to resist corrosion.

Main Applications

Transfer from the Collection Tank

- HS Pump: Used for transferring treated sludge directly from the filter press to collection bins.

- N Pump: Perfect for transferring sludge in wastewater treatment processes and managing chemical-physical effluents.

Transfer to the Filter Press or Incinerator Dryer from Collection Tanks

- N Pump: Ideal for pumping thickened sludge to centrifuges or screw presses for dewatering.

- HSB Pump: A hopper pump specifically designed for transferring sludge from silos to the dryer or incinerator, the final stage of treatment for removing residual moisture.

- V Pump: Installed vertically in tanks for transferring liquid sludge with minimal footprint and maximum operational efficiency.

Strengths

We are a reliable partner in the sludge treatment sector, offering customized solutions and a complete range of progressive cavity pumps designed to meet specific needs. With years of experience and national and international references, we provide:

- Advanced technology for transferring thickened and dewatered sludge, even with dry matter content of up to 40%.

- Reliability and long-lasting performance, thanks to robust construction and the use of high-performance materials.

- Optimization of storage and transfer processes, reducing plant downtime and ensuring efficient management of the treatment cycle.

Each of our pumps is developed in compliance with the strictest industrial standards, ensuring high quality and consistent performance over time.

A Commitment to Efficiency and the Environment

We stand alongside companies in the wastewater treatment sector, providing solutions that enhance process efficiency and reduce environmental impact. With robust, reliable, and customized pumps, we ensure operational continuity and resource optimization, addressing the challenges of an increasingly sustainability-focused industry.

Choosing our company means partnering with a provider that combines advanced technology, solid experience, and environmental awareness to deliver tangible and lasting results.

Recommended products