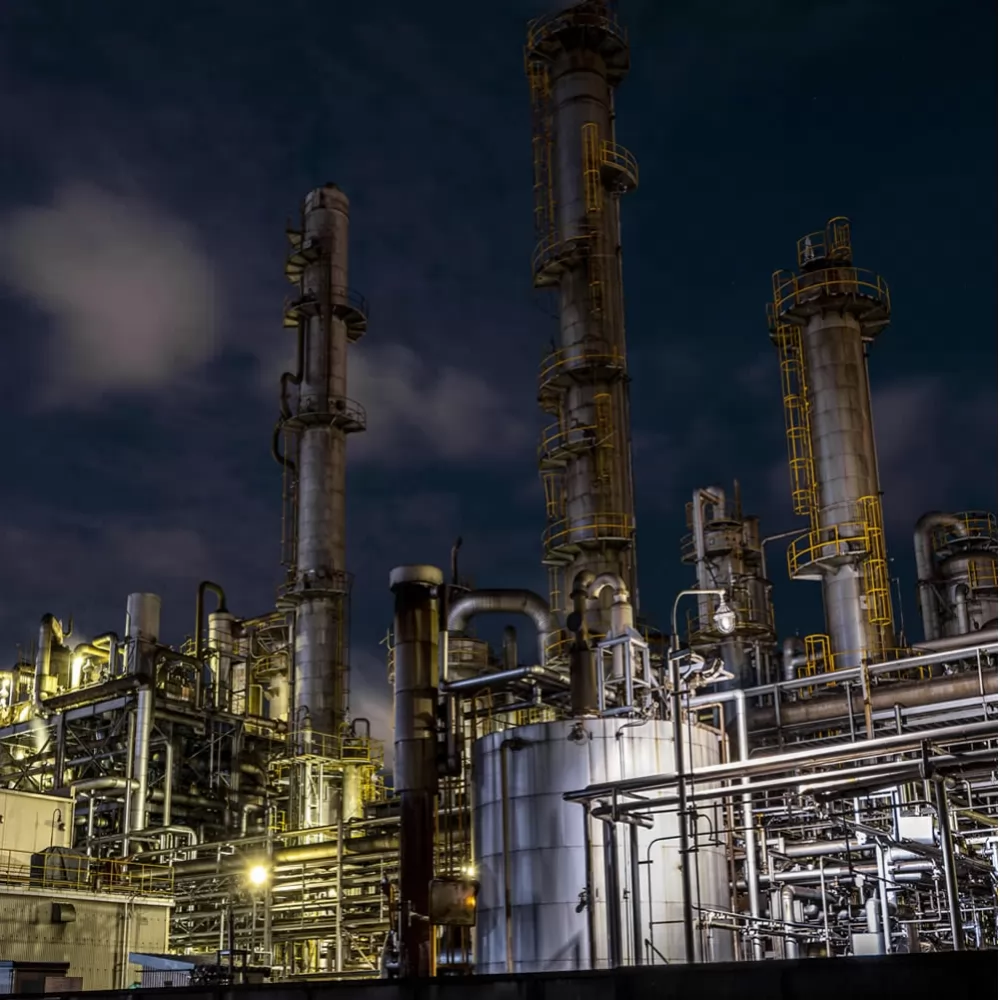

Onshore-Offshore Platforms

Pumps ideal for handling extreme onshore and offshore conditions.

Onshore and offshore platforms represent a complex and highly specialized environment, where the safety, precision, and reliability of equipment are essential. From extraction processes to fluid treatment and transportation, every phase requires solutions capable of operating in extreme conditions, ensuring high performance and minimizing operational risks.

Challenges and Innovations:

The oil and gas industry constantly faces challenges related to safety, efficiency, and environmental sustainability. To address these challenges, there is a continuous drive for innovation in rotating equipment technology. Advancements such as predictive maintenance, improved materials for greater durability, and the development of more efficient pump designs are revolutionizing the industry.

Pumps are used to transport fluids such as crude oil, petroleum refining liquids and wastes, and water during production and refining processes.

Available for a wide range of onshore and offshore applications, Nova Rotors pumps meet the main requirements of the oil and gas industry.

We offer a wide range of products, services, and expertise to find the most suitable configuration based on the client's specific needs. This allows us to select the appropriate pump, considering factors such as fluid properties, pressure, temperature, and flow rates, to ensure optimal performance and reliability.

The progressive cavity pumps meet the most stringent maintenance requirements, preventing failures and ensuring uninterrupted operations. Factors like accessibility for maintenance, availability of spare parts, and reliability play a significant role in equipment selection. We understand this, which is why we have developed a structure that guarantees efficiency, flexibility, and a quick response to customer requests, making us the best possible partner. Nova Rotors Oil & Gas teams are ready to offer highly responsive, customized services, including engineering and design, project management, quality assurance systems, quality control, field services, and training.

The progressive cavity design of our pumps offers precise flow control at variable speeds, allowing operators to finely adjust flow rates to suit production needs. This flexibility ensures efficient energy use and minimizes waste, contributing to the overall profitability of our customers' operations.

We are committed to understanding the needs of your applications to properly apply our designs. We don’t just sell pumps; we sell pumps that work in complex systems, and understanding how our equipment interacts can make the difference between failure and success.

Nova Rotors’ progressive cavity pumps are designed to meet these needs, offering reliable technology for handling high-viscosity fluids, abrasive fluids, or fluids containing solid particles, typical of onshore and offshore applications. Available in Atex versions for explosive zones and with Atex IECEX motors.

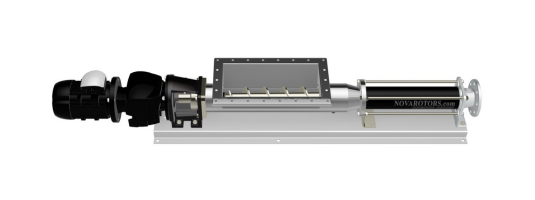

Nova Rotors pumps for onshore-offshore platforms.

N SERIES PUMPS

Flanged industrial series, ideal for heavy-duty applications. It is the best solution for the industrial sector for pumping a wide range of fluids, including crude oil, drilling mud, and produced water. Available with flanged UNI, DIN, and ANSI connections, as well as GAS BSP threaded connections.

VERTICAL SERIES

Vertical series designed for pumping from tanks and wells, immersed directly in the product to be pumped. The length can be adjusted to meet installation requirements. The stainless steel version (AISI 304 or AISI 316) is supplied with a stator "sleeve" as standard to prevent stator corrosion. Two standard configurations are available: the short version and the long version with a deep well base frame and a guide cone mounted at the bottom.

It is also suitable for petroleum liquids, including pumping waste oil and drilling residues.

M SERIES METERING PUMPS

Metering pumps are used for pumping and dosing small quantities.

They are also used for the precise dosing of chemicals (e.g., flocculant dosing to assist in the separation process), for supplying lubricant fluid in controlled doses to the multiphase pump, and for adding chemicals to control pH and inhibit corrosion.

On The N series progressive cavity pump, there is a special API version, featuring a base designed according to API 676 and the possibility of mechanical seals compliant with API 682, making it ideal for use in the oil and gas sector.

Main Applications

Handling of Abrasive Fluids

N Pumps: Handling of drilling muds, cement, and other dense mixtures used in extraction and processing operations.

Crude Oil Pumping

N Big Size Pumps: Safe and efficient transfer of extracted oil, even at high viscosity, from platforms to processing or storage units.

Chemical Fluid Transfer

M Dosing Pumps: Handling of chemicals required for treatment and maintenance of offshore facilities.

Waste Fluid Disposal

Pumping and management of waste fluids and wastewater from onshore and offshore operations.

Applications in Explosion-Risk Areas

ATEX-certified pumps, ideal for operating in classified explosive environments.

V Series Vertical Pumps - Suitable for Emptying Large and Small Tanks

Ideal for handling viscous and dense liquids, making them particularly useful in the oil & gas sector and refineries. These pumps are designed to handle fluids ranging from crude oil, bitumen, and resins to chemicals and heavy fuels. Some specific examples include crude oil (often with high viscosity), refined products, residues, and processing waste containing solid or sandy particles.

Advantages

Nova Rotors pumps offer superior efficiency, low pulsation, and gentle handling of sensitive fluids, making them the optimal choice for industries such as oil & gas, food processing, and mining. Oil & gas applications often involve handling fluids with high particle content, such as sand, limestone, and other abrasive solids. Nova Rotors progressive cavity pumps are designed to handle these challenging materials without compromising performance or durability, ensuring reliable operation even in the most demanding pumping scenarios.

Low Maintenance and Troubleshooting

With a simple construction and easy access for maintenance, Nova Rotors pumps minimize downtime and maintenance costs. The modular design allows for quick and easy access to critical components for servicing and repair. High-quality materials and precision engineering ensure a long lifespan, reducing downtime and maintenance costs for our clients.

API 676 Compliance

API 676 covers a wide range of rotary positive displacement pumps, including progressive cavity pumps used in various industries, from oil & gas to chemical processing and beyond. While setting comprehensive guidelines, API 676 allows some flexibility in design to meet specific customer needs and operational conditions.

As an internationally recognized standard, API 676 is widely adopted worldwide, promoting quality, safety, and interoperability in rotary positive displacement pump systems. Nova Rotors progressive cavity pumps are designed to fully comply with API 676, ensuring the highest levels of safety, performance, and reliability in demanding applications.

Capable of handling a wide range of fluids, including high-viscosity, abrasive, and solid-laden materials, Nova Rotors PCP pumps are the ideal choice for the most challenging oil & gas applications. Our pumps effortlessly adapt to variable process conditions, maximizing productivity and minimizing the need for expensive auxiliary equipment. The low-shear design ensures that delicate fluids are transferred without degradation or separation. Nova Rotors pumps also guarantee high separator efficiency, causing almost no damage to oil droplets and eliminating the risk of creating difficult-to-separate emulsions.

No additional auxiliary devices are required, as our pumps are fully self-priming. The NPSH requirement of our pumps is very low, which is beneficial when considering tank emptying applications such as closed drain drums, KO (knock-out) vent drums, or any application involving liquids with high vapor pressure.

Our field-proven technology effectively handles a wide range of hydrocarbons. Nova Rotors pumps provide a constant, smooth, and non-pulsating flow. The volume remains virtually unchanged despite viscosity variations, ensuring accurate flow readings downstream and eliminating the need for expensive pulsation dampeners required with alternative pumps.

Key Strengths

Our extensive experience in onshore and offshore pump applications allows us to provide innovative and robust solutions capable of tackling the most challenging conditions.

Durability in Extreme Environments: Our pumps are built with highly corrosion-resistant materials, such as stainless steel and special alloys, ideal for operating in saline environments and extreme temperatures.

Reliability and Consistent Performance: Designed for uninterrupted operation, reducing maintenance costs and downtime.

Handling of Complex Fluids: Ideal for pumping viscous, abrasive fluids or those containing solid particles, thanks to a design that minimizes wear and ensures long service life.

Compliance with International Regulations: All pumps meet the strictest safety and quality standards, including ATEX certification for use in explosive risk zones.

With a complete range of products and a dedicated team of experts, we are the reference partner for reliable and advanced pumping solutions in the energy sector.

Commitment to Efficiency and the Environment

We work hard to provide solutions that combine operational efficiency with environmental responsibility, minimizing the ecological impact of energy operations. The use of durable materials and advanced technologies ensures reliable performance and greater safety for operators and the environment.

With us, onshore and offshore platforms can rely on a partner that combines experience and innovation, responding to industry challenges with sustainable and reliable technologies.

Recommended products