Brewing Industry

Pumping Solutions for the Brewing Industry

Monovite pumps are essential for the brewing sector, ensuring the delicate and efficient transfer of wort, beer, and by-products of the brewing process. Thanks to their progressive cavity technology, these pumps provide a constant, pulsation-free flow, ideal for handling viscous liquids, yeasts, and ingredients sensitive to oxidation.

In industrial beer production, monovite pumps are used for several operations, including:

- Transferring wort during various stages of production.

- Handling yeasts and solid suspensions without altering product quality.

- Precisely dosing additives and technological aids.

- Managing by-products such as spent grains and fermentation sludges.

A significant advantage of monovite pumps is their gentle product handling, preventing aeration and foaming that could compromise product quality.

Nova Rotors pumps for industrial breweries

MX Series Sanitary Dosing Progressive Cavity Pump

Ideal for the precise dosing of yeasts, additives, and stabilizers. Ensures uniformity and accuracy, reducing waste and optimizing product quality. Hygienic design for optimal cleaning. 3-A Sanitary Standard certified, EHEDG compliant.

X Series Sanitary Progressive Cavity Pumps

Perfect for the gentle transfer of wort and beer without altering flavor. Progressive cavity technology ensures a constant, pulsation-free flow. Stainless steel construction, 3-A Sanitary Standard, FDA compliant.

Sanitary Progressive Cavity Pumps HX Series

Hopper progressive cavity pump, widely used in the olive oil production industry for transferring olive paste efficiently and reliably.

progressing cavity pumps MXF Titanium

The ideal uncompromising choice for breweries, thanks to its 3-A certified sanitary design, compliant with EHEDG, ensuring maximum hygiene and easy cleaning (CIP/SIP).

Perfect for the gentle transfer of: Hot and cold wort, Yeasts and starter cultures, Finished beer (without altering its properties), Syrups and liquid sugars for fermentation, Flavors and additives for specialty beers.

Thanks to its stainless steel construction, Titanium rotor and the total absence of dead zones, it ensures efficiency and safety in the production process.

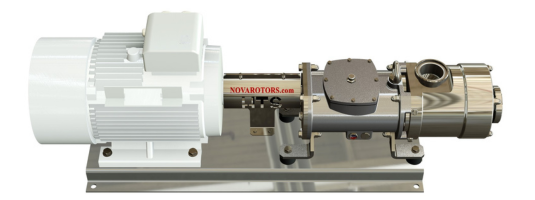

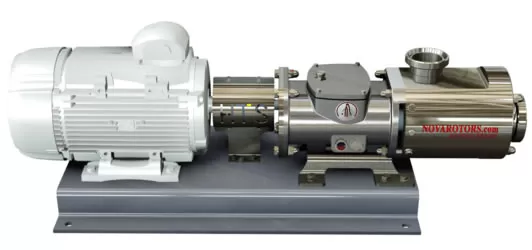

Stainless Steel Twin Screw Pumps HTS Raptor Series

Ideal for transferring wort, beer, and sensitive products without altering their organoleptic properties. Stainless steel construction with 3-A Sanitary Standard certification for maximum hygiene and corrosion resistance. Constant, pulsation-free flow, ensuring delicate product handling. Compatible with CIP and SIP systems for effective and safe cleaning. High efficiency and reliability, reducing downtime and optimizing production processes. EHEDG compliant.

Main Applications

Wort Transfer

The X and HX Series pumps ensure homogeneous transport without introducing air, preventing unwanted oxidation.

Yeast Management

The MX and HX Series pumps allow for the gentle handling of yeast, preserving its cellular structure and fermentative potential.

Additives and Stabilizers Dosing

The MX Series pumps enable precise and controlled dosing, optimizing the final product's quality.

Spent Grains and Fermentation Sludge Handling

The HX Series pump HXF version, are ideal for managing by-products, ensuring effective removal of spent grains and fermentation residues.

Wort and Finished Beer Transfer

The HTS Raptor Series twin-screw pumps ensure gentle transfer, preserving organoleptic properties. These pumps are ideal for viscous liquids like syrups and malt concentrates, as well as for handling yeasts and solid suspensions without damaging their integrity, crucial for optimal fermentation. They are also perfect for sensitive substances, such as unpasteurized craft beers, avoiding thermal shocks or unwanted variations.

Advantages of Nova Rotors Monovite Pumps for Breweries

- Gentle Handling – No alteration of the wort and beer quality due to pulsation-free transfer.

- Certified Hygiene – Materials comply with FDA and 3-A Sanitary Standards for a safe production environment.

- Efficiency and Reliability – Suitable for continuous processes with reduced maintenance needs.

- Versatility – Ability to handle both low-viscosity liquids and denser products like spent grains and sludge.

- Simplified Cleaning – Compatible with CIP and SIP systems for effective sanitation without disassembly.

Nova Rotors' Diamond Series monovite pumps offer a strategic solution for industrial breweries, enhancing production efficiency and ensuring the highest quality of the final product.

Recommended products