Pharmaceutical Industry

Our Precise, Hygienic, and Reliable Pumps for the Pharmaceutical Sector

The pharmaceutical industry demands precision, reliability, and extremely high hygiene standards. Every stage of drug and healthcare product production, from raw material processing to final packaging, must ensure the utmost purity and product integrity. For this reason, Nova Rotors pumps are the ideal solution, designed to operate in controlled environments and comply with the most stringent international regulations.

With their gentle and consistent transport capabilities, our monovane pumps ensure the integrity of fluids, even in the presence of viscous products or those containing micro-particles. They guarantee a pulsation-free flow and minimize mechanical stress.

Nova Rotors Pumps for the Pharmaceutical Sector

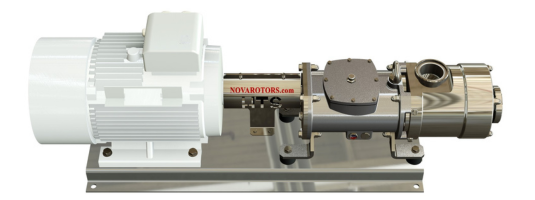

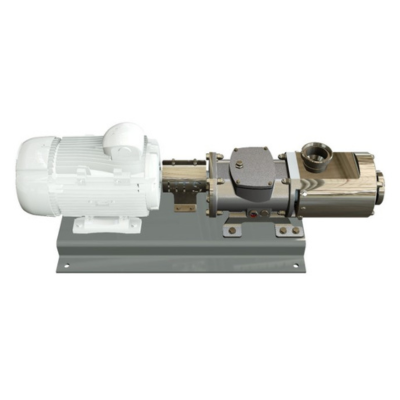

HTS Twin-Screw Pumps

An advanced solution for fluid transfer in the pharmaceutical sector, ensuring hygiene, precision, and gentle pumping. Their ability to handle fluids of varying viscosities, even with suspended particles, makes them ideal for multiple pharmaceutical and biotechnological applications. 3-A certified.

X Series Pumps

Transfer of syrups, emulsions, and pharmaceutical solutions with high precision.

Pumping of gels, creams, and viscous products without altering their structure. Handling of active ingredients and delicate compounds in production processes.

HX Series Hopper Pumps

Pumping of dense pastes and semi-solid products used in pharmaceutical formulation.

Transfer of creams, ointments, and pharmaceutical pastes with optimal viscosity control.

Loading and handling of raw solid materials mixed with liquids.

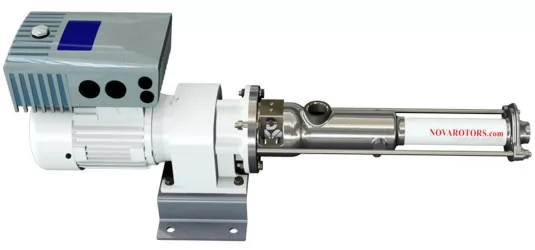

MX Dosing Pump

Precise dosing of active ingredients and pharmaceutical solutions in formulation processes.

Controlled filling of vials, tubes, and containers with consistent volume.

Integration into production lines for liquid medications and suspensions.

MXF Dosing Pump

Titanium Shaft, Joint-Free Design: High levels of hygiene with 3-A certification.

Transfer of highly corrosive or particularly delicate products, leveraging titanium’s resistance.

Safe and contamination-free pharmaceutical fluid handling.

Suitable for sterile environments and CIP/SIP processes, ensuring thorough cleaning and sterilization.

Main Applications

Transfer of Viscous and Sensitive Fluids

The X pumps are ideal for moving syrups, ophthalmic solutions, creams, and ointments with delicate transport that preserves the product’s integrity.

Transfer of Liquids and Viscous Products

The HTS twin-screw pumps are perfect for transferring such fluids, offering high hygiene standards certified by 3-A and equipped with CIP (Clean-In-Place) and SIP (Sterilize-In-Place) capabilities, preventing costly machine downtimes. All product-contacting parts are made of stainless steel.

Active Ingredient Dosing

The MX pumps provide precise and controlled dosing of pharmaceutical active ingredients during mixing and formulation stages.

Filling and Packaging Processes

The X pumps ensure accurate and pulsation-free transfer of liquids and gels to filling and final packaging lines.

Movement in Aseptic Environments

The XF pumps are ideal for sterile plants and clean rooms, with hygienic design that facilitates CIP and SIP operations.

Handling Materials with Solid Particles

The HX pumps offer perfect solutions for products containing micro-granules or particles, preserving their structure and characteristics.

Strengths

With extensive experience in managing complex and delicate fluids, we provide a wide range of solutions tailored for the pharmaceutical sector. Our hygienic pumps are specifically designed to meet the critical requirements of pharmaceutical production lines:

- Highest Hygiene Standards: Design without dead zones to prevent stagnation and facilitate sanitation. All materials in contact with the product comply with FDA and EHEDG standards, with 3-A certified pumps.

- Precision and Control: Gentle pumping and extremely accurate dosing, perfect for liquid and viscous products.

- Reliability and Durability: Solutions designed to minimize downtime and reduce maintenance costs with robust, high-quality components.

- Customization and Flexibility: The ability to adapt pumps to the specific needs of production processes, ensuring optimal performance.

We are the ideal partner for pharmaceutical companies looking for advanced solutions for safe, efficient production that complies with global standards.

A Commitment to Efficiency and the Environment

Providing advanced pumping solutions for the pharmaceutical industry, with a focus on operational efficiency and environmental sustainability, is our top priority. The use of certified materials and hygienic processes ensures maximum product and environmental safety, reducing waste and optimizing production performance.

Choosing us as a partner means benefiting from cutting-edge technologies capable of addressing the most complex challenges with reliable, compliant, and future-oriented solutions.

Recommended products