Dairy Industry

Preserve the stability of dairy products with our highly hygienic pumps

The dairy industry is one of the key pillars of the food sector, encompassing products such as milk, yogurt, butter, and both stringy and creamy cheeses. Gentle handling of these products is essential to preserve their organoleptic properties, quality, and integrity.

For example, in yogurt production containing fruit pieces or cereals, delicate pumping is crucial to prevent damage to the solid components and maintain the product’s structure. Similarly, cheese processing requires pulse-free transfer with low shear stress to ensure consistent quality in the final product.

Moreover, since most dairy products contain enzymes and probiotic bacteria, it is essential to use hygienic equipment that is easy to clean to prevent contamination. Our progressive cavity pumps perfectly meet these requirements, ensuring efficient and sanitary fluid transfer throughout the entire production process.

Nova Rotors Pumps for the Dairy Industry

XO DIAMOND SERIES

Hygienic open-joint pump made of stainless steel, free of dead zones and stagnation points. Ideal for pumping semi-dense products and delicate liquids.

HXO DIAMOND SERIES

Hopper version with a hygienic open joint in stainless steel, perfect for transferring products containing solid pieces or with high viscosity.

HXC DIAMOND SERIES

Hopper version with compact joint with rubber sleeve and shaft in stainless steel, perfect for transferring products containing solid pieces or with high viscosity.

XC DIAMOND SERIES

Pump with a standard Diamond joint, designed for the precise dosing of additives, enzymes, and solutions used in mixing and fermentation processes.

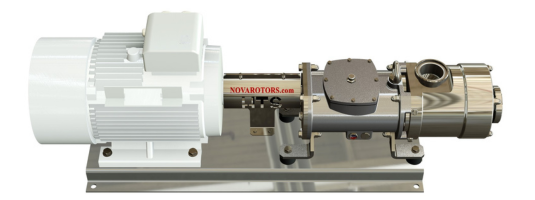

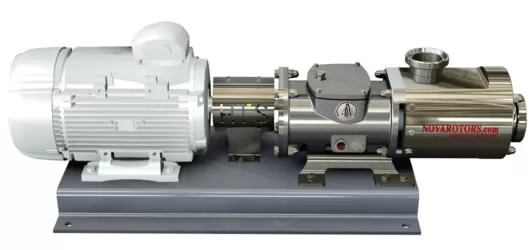

Pump HTS Twin-Screw Pumps for the diary Industry

The HTS Twin-Screw Pump is ideal for the dairy industry, ensuring gentle and efficient transfer of:

Milk and dairy liquids,Soft cheeses and creamy products, yogurt with fruit pieces – maintaining product integrity, whey and dairy by-products

Designed for hygiene and compliance with FDA andEHEDG, certified and 3-Ac Sanitary standards, it guarantees high performance with minimal product shear.

Main Applications

Butter Handling

The XO pump with a hygienic joint ensures the gentle transfer of butter to the forming machine and packaging, providing a constant, pulsation-free flow.

Yogurt Production with Fruit Pieces

The X pump allows for the handling of yogurt containing fruit pieces or cereals without damaging their structure, preserving the product's organoleptic properties.

Milk and String Cheese Transfer

The X pump is ideal for transferring milk, creamy, or stringy cheeses, thanks to a gentle pumping action that minimizes stress on the product.

Dosing of Additives and Enzymes

The XC pump is used for the precise dosing of enzymes and additives during milk and cheese processing.

Ready Juice Transfer

The stainless steel XO pump with an open, sanitizable joint is perfect for transferring ready-to-drink juices or other delicate liquids, ensuring high hygiene standards.

Key Strengths

With extensive experience in the food industry, we provide customized pumping solutions for dairy products. Our range of pumps is designed to ensure hygiene, reliability, and high performance, meeting the most specific demands of modern production lines.

- Nova Rotors pumps offer:

Gentle handling of viscous, semi-dense products or those containing solid pieces, such as fruit yogurt and creamy cheeses. - Advanced hygienic design, compliant with FDA regulations and MOCA (EC) No. 1935/2004, with options certified 3-A Sanitary Standard upon request.

- Certified materials tested for food-grade applications, including elastomer stators and stainless steel rotors.

- Easy maintenance, with innovative solutions like sanitizable open joints and cartridge seals that reduce replacement times.

Nova Rotors pumps provide pulse-free transport and controlled movement, optimizing every stage of processing—from dosing and pasteurization to final packaging.

A Commitment to Efficiency and Sustainability

We support the dairy industry with advanced pumping solutions that ensure efficiency, hygiene, and waste reduction. Each of our pumps is designed to preserve product quality, optimize transfer times, and reduce operational costs. Compliant with the strictest sanitary regulations, we are committed to providing reliable, easy-to-clean, and durable pumps, contributing to a sustainable and cutting-edge production process.

Choosing us means relying on experts who combine technological innovation, absolute hygiene, and environmental awareness, delivering tangible results at every stage of dairy processing.

Recommended products