Bakery Goods and Food Creams

Pumping Solutions for the Baking Industry

Progressive cavity pumps, also known as single-screw pumps, play a crucial role in the baking industry for various dough-handling and processing applications. These pumps operate on the principle of a helical rotor rotating within a durable stator, creating a continuous seal along the pumping chamber.

Pumping Solutions for the Baking Industry

In the baking industry, progressive cavity pumps are commonly used for tasks such as transferring dough from mixing stations to shaping or molding equipment, precisely dosing dough into trays or molds for baking, and circulating dough along production lines. Their gentle pumping action ensures that the integrity of the dough is preserved, preventing damage to its structure and texture.

A key advantage of progressive cavity pumps in bakery applications is their ability to handle highly viscous and shear-sensitive materials with minimal disturbance. This is essential for maintaining dough quality, especially in processes that require precise control of flow rates and pressure.

Nova Rotors pumps are often equipped with features such as adjustable speed control and the ability to reverse flow, providing greater flexibility in baking operations. They can adapt to different production requirements, ensuring a consistent and uniform dough handling process from start to finish.

Overall, the use of progressive cavity pumps in the baking industry highlights their importance in optimizing dough management efficiency, maintaining product quality, and improving overall productivity in bakery operations.

Nova Rotors Pumps for Pastry and Baking

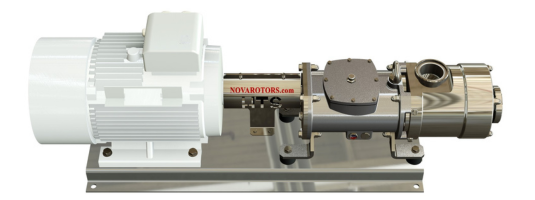

Sanitary Dosing Pump MX

Ideal for the precise dosing of creams and mixtures, ensuring uniformity and accuracy while reducing waste and optimizing production.

Sanitary Dosing Pump MXF

Unlike the previous model MX, its joint-free titanium transmission ensures exceptional sanitation, eliminating stagnation points for maximum hygiene, certified according to 3-A Sanitary Standards. We produce also EHEDG version.

Sanitary Progressive Cavity Pumps X and XF

Perfect for transferring large quantities of pastry creams and leavened dough, ensuring gentle pumping that preserves the product’s structure. manufactured according to 3-A Sanitary Standards and EHEDG.

Sanitary Dosing Pump MXF

Unlike the previous model X, its joint-free titanium transmission ensures exceptional sanitation, eliminating stagnation points for maximum hygiene, certified according to 3-A Sanitary Standards and EHEDG.

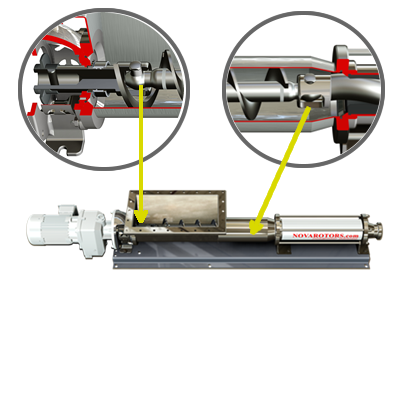

Sanitary Hopper Progressive Cavity Pumps HX and HXO

Equipped with an integrated auger, they facilitate the feeding of dough into the pump’s stator and rotor, ensuring a continuous and uninterrupted flow. The HXO with open joint is the solution with the best sanitization features, thanks to a casing and rotating components designed without dead zones or stagnation points. The pin-type joint is specifically sized to ensure long-lasting durability. Its open-design lubrication system allows the pumped product itself to lubricate the joint, making it ideal for non-abrasive fluids. Performance is significantly enhanced when pumping lubricating products.

Pump Hygienic Twin-Screw Pumps for the Bakery Industry

Hygienic twin-screw stainless steel pumps are an excellent solution for the bakery industry, ensuring efficient and gentle transfer of doughs and food creams. With their advanced design, these pumps provide continuous and uniform pumping while preserving product structure and quality.

Main Applications

In the bakery industry, progressive cavity pumps can be used to handle a variety of materials, including:

- Dough: The X and MX series pumps are suitable for transferring doughs of different consistencies, from soft doughs for bread and pastry production to denser doughs for rustic bread varieties.

- Fillings and toppings: The MX dosing pumps can be used to transfer fillings and toppings such as custard,

- Glazes and coatings: The MX dosing pumps are also ideal for transferring glazes, coatings, and syrups used to decorate and finish bakery products like muffins, donuts, and decorated cakes.

- Industrial sauces and condiments: The X and MX pumps can handle sauces, condiments, and other ingredients used to add flavor or moisture to baked goods, such as pizza sauces, sandwich spreads, or focaccia preparations.

In general, progressive cavity pumps offer high precision in dosing and material transfer, enabling accurate control of flow rates and quantities, making them useful for a variety of applications in the baking sector.

Hygienic Progressive Cavity Pumps for the Food Industry

Another key advantage of progressive cavity pumps is their hygienic design. Many of these pumps are made of stainless steel, a material that is easy to clean and resistant to corrosion. Additionally, the X series pumps are designed in compliance with EN 1935 regulations (also known as MOCA – "Materials and Objects in Contact with Food"), which define materials intended to come into contact with food. They also comply with FDA (Food and Drug Administration) regulations in the United States and 3-A Sanitary Standards, which establish hygiene requirements for the food industry.

Compliance with these standards and 3-A certification ensures that the pumps are designed and built to meet strict sanitary requirements, guaranteeing no risk of product contamination during the pumping process. This is especially important in the food industry, where product safety and quality are paramount.

Furthermore, progressive cavity pumps designed for the food industry often feature additional characteristics to facilitate cleaning and sterilization, such as smooth, cavity-free surfaces, a hygienic design, and easy access to components for maintenance. These factors further contribute to ensuring that the pumps are safe, sanitary, and fully compliant with food industry regulations, making them an ideal choice for bakery applications.

Key Advantages

✔ Gentle product handling: Progressive cavity pumps provide smooth and gentle pumping action, making them ideal for sensitive materials prone to cavitation or separation, such as delicate doughs.

✔ Adaptability to viscosity: These pumps can handle materials with a wide range of viscosities, from liquid to highly dense substances. This flexibility makes them suitable for various applications, including thick creams and glazes.

✔ Precision dosing: Progressive cavity pumps allow for precise control of flow and volume, making them ideal for applications requiring accurate dosing, such as fillings or glazes in bakery products.

✔ Reliability and low maintenance: These pumps are robust and require minimal maintenance, ensuring continuous operation in industrial environments.

✔ Compact design and easy installation: Their compact size allows for seamless integration into existing production lines, making them convenient for tight spaces and pre-existing setups.

In summary, progressive cavity pumps offer a combination of gentle material handling, operational flexibility, precise dosing, and reliability, making them a highly beneficial choice for various industrial applications, including the bakery sector.

Recommended products