Papermaking Industry

Continuous and Gentle Pumping for Paper Production

The production of paper has ancient origins, dating back to China in 105 AD, where it was made using mulberry tree bark. Over the centuries, the secret of its manufacturing process slowly spread, reaching Europe around the 9th century thanks to Arab merchants. In Italy, historic paper mills, active since the 12th century, have made a significant contribution to the industry, establishing the country as a European benchmark.

Today, the paper industry is a leading and constantly evolving sector, driven by the introduction of advanced technologies aimed at increasing production efficiency and reducing operating costs. Our progressive cavity pumps play a key role in every stage of the production cycle, ensuring reliable and precise transport of high-viscosity fluids and materials, such as paper pulp, dyes, and wastewater from processing operations.

Nova Rotors Pumps for the Paper Industry

N Pumps

Flanged Industrial Pumps – Ideal for transferring dyes, fixatives, fillers, and wastewater in paper forming and treatment processes.

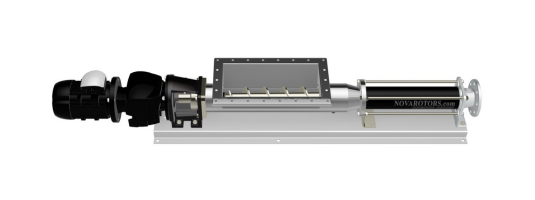

H Pump

Basic Version with Hopper and Screw Conveyor – Ideal for pumping low-flowing and fibrous materials without bridge formation.

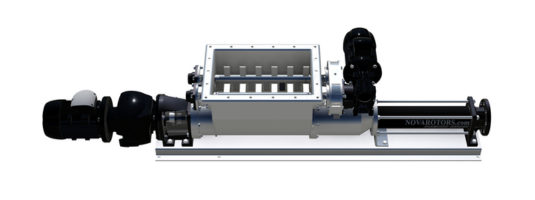

HB Pumps

Hopper Pump with Twin-Shaft Bridge Breaker – Designed for extremely high-viscosity materials prone to block formation, such as rag-based paper pulp.

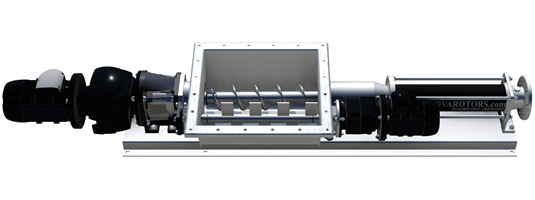

HP Pumps

Equipped with a Wide Hopper and Independent Bridge-Breaking Blades – Ideal for pumping recycled paper pulp, ensuring a constant and reliable flow.

Main Applications

Transfer of Cellulose Pulp

The DH pump is used for transferring cellulose pulp to the dosing system, regardless of the pulping method (mechanical or chemical).

Pumping Recycled Paper Pulp

The DHP pump with bridge-breaking blades ensures continuous transfer of paper pulp obtained from recycled paper, preventing bridge formation.

Pumping Rags Pulp

The DHB pump is specifically designed for transferring pulp derived from rags with varying fiber lengths, avoiding operational interruptions.

Transfer of Auxiliary Substances

The DN pump ensures precise, pulsation-free dosing of dyes, fillers, and fixatives from storage tanks to the dosing system.

Management of Wastewater

The DN pump is used for transferring wastewater generated during various processing stages (pressing, filtering, bleaching, and coating) for subsequent treatment.

Strengths

We have extensive experience in the paper industry, providing advanced solutions designed to meet the specific needs of modern paper mills. With innovative products, dedicated services, and a team of experts, we can offer the ideal configuration for every production phase.

Our progressive cavity pumps are designed for pumping fibrous fluids such as cellulose pulp, auxiliary substances (resins, kaolin, dyes), and industrial wastewater. They provide:

- Efficient and precise transport, free from pulsations, with adjustable rotational speed.

- Simplified maintenance, thanks to the adoption of cartridge seals that reduce replacement time.

- Reduction of operating costs, with optimal performance and long lifespan even in the most demanding applications.

Each of our pumps is developed in compliance with the strictest industrial standards, ensuring quality, reliability, and optimized transfer in every stage of processing.

A Commitment to Efficiency and the Environment

We support the paper industry with advanced technological solutions that optimize production processes, reduce operating costs, and promote environmental sustainability. Our pumps ensure efficiency, durability, and reliability even in the most complex applications, helping to make the paper industry more innovative and competitive.

Choose Nova Rotors for tangible and lasting results in every stage of paper production.

Recommended products