Biogas

Pumps for Biomass Handling and Energy Production

Biogas production offers a tangible solution to the growing demand for renewable, sustainable, and cost-effective energy. Utilizing organic materials to generate electrical and thermal energy not only reduces emissions but also provides significant benefits, such as the production of digestate, a natural fertilizer, and the reuse of heat generated in cogeneration processes.

With over ten years of experience in the biogas sector, we provide tailored solutions designed to tackle the most complex challenges related to the handling of biomass, sludge, and organic materials, ensuring reliability, efficiency, and durability. Our range of progressive cavity pumps—developed according to the most stringent international standards—optimizes every phase of the production process, minimizing operational costs and ensuring continuous operation, a crucial aspect for facilities where downtime can incur significant expenses.

Our Pumps for the Biogas Sector

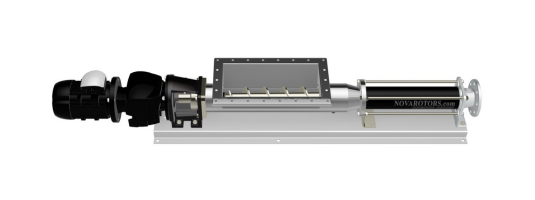

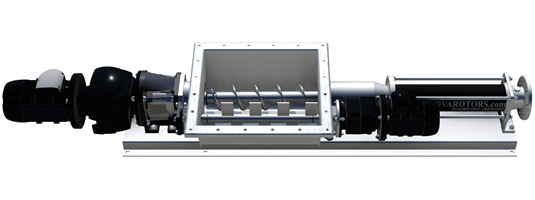

HS-T SERIES

Rectangular Hopper Pump Ideal for pumping silages with the injection of liquids such as slurry or digestate. The wide hopper incorporates an auger to facilitate feeding to the hydraulic pump, while the rectangular bottom separates stones catcher and other foreign objects, ensuring safe and reliable operation.

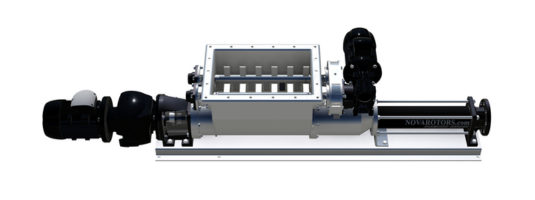

HS-R series

The Nova Rotors Diamond HS-R progressive cavity pump with hopper is the result of further development of the Nova Rotors HS and HST pumping solutions, specifically designed for large biogas plants. This single-screw pump features a rectangular hopper with an inspectable collection basin, making it ideal for the transportation and mixing of solid and liquid materials. Thanks to its rear injection capability, the entire volume of the hopper is utilized for effective material mixing.

N SERIES

Suitable for the most demanding applications. Perfect for transferring slurry, mixed biomass, and digestate, it ensures efficiency and durability thanks to its robust construction.

V SERIES

Designed for direct pumping from tanks or wells. Fully customizable in length, it features stainless steel versions (AISI 304 or AISI 316) with a stator cover jacket to prevent corrosion, ensuring a compact footprint and maximum reliability.

H SERIES

Designed for pumping low-flowability substances that tend to form bridges, ensuring a continuous and steady flow.

Main Applications

Transfer of Biomass to the Digester

The HS-T or HS-R pump, combined with an N pump for slurry injection, manages the transfer of solid biomass (such as corn, grass, and organic waste) to the digester, ensuring a perfectly mixed and pumpable fluid.

Pumping of Livestock Waste

The N pump is ideal for collecting and transferring livestock waste from farms equipped with grid collection systems, optimizing space and footprint.

Transfer of Slurry and Silages

The N pump allows for the pumping of slurry mixed with 5% silages from collection tanks directly to the digester, maintaining an efficient and constant flow.

Vertical Pumping from Tanks

The V pump, installed directly in slurry collection tanks, is immersed in the fluid to be pumped, eliminating the need for suction pipes and reducing footprint.

Digestate Discharge

The DN pump is designed for transferring digestate from the post-digester to final storage tanks, ensuring operational continuity and reliability.

Strengths

- Customized solutions designed for transferring complex fluids, high viscosity materials, or those containing solid bodies.

- A wide range of products that optimize feeding, mixing, and discharge phases.

- Advanced technologies that meet the needs for energy efficiency, reliability, and reduced operating costs.

Accessories

Wide possibilities for square bases, sensors, and much more.

Our pumps are designed to work with fluids derived from agricultural biomass, livestock waste, agro-industrial byproducts, and organic materials with a high dry matter content, maintaining high performance even in the most demanding operating conditions. Examples include offal, whole crop silage, liquid animal manure, corn silage, straw, grass, slaughterhouse waste, fruits, vegetables, food waste, pomace, sugar beets, onions, and return liquid from the digester.

A Commitment to Efficiency and the Environment

We are the ideal partner to support the growth of the biogas sector with innovative solutions that enhance process efficiency, reduce operating costs, and promote the use of renewable energy. Each of our pumps is designed to meet the most complex challenges of the industry, ensuring reliability, durability, and excellent performance.

Discover how Nova Rotors pumps can optimize your biogas plant and contribute to your sustainable growth.

Recommended products